Iron oxides are compounds that are composed of iron and oxygen with a chemical composition of Fe203 and commonly referred to as haematite.

Minchem HMP Iron Oxide has a typical chemical composition of: –

It is used in foundries as a mould and core additive to suppress nitrogen and therefore reducing gas porosity defects. It also reduces expansion defects such as finning and veining.

Minchem HMP Ltd hold large stocks in the UK and all grading takes place at our UK processing sites.

We offer tailor-made grades with a full range of packaging requirements.

MSDS and TDS are available upon request.

Minchem HMP Chrome Sand originates from South Africa and has the following characteristics

Extensively used as a mould and core sand in Iron and steel foundries. It is also used as a refractory additive in the production of steel

We offer a full range of packaging requirements.

MSDS and TDS are available upon request.

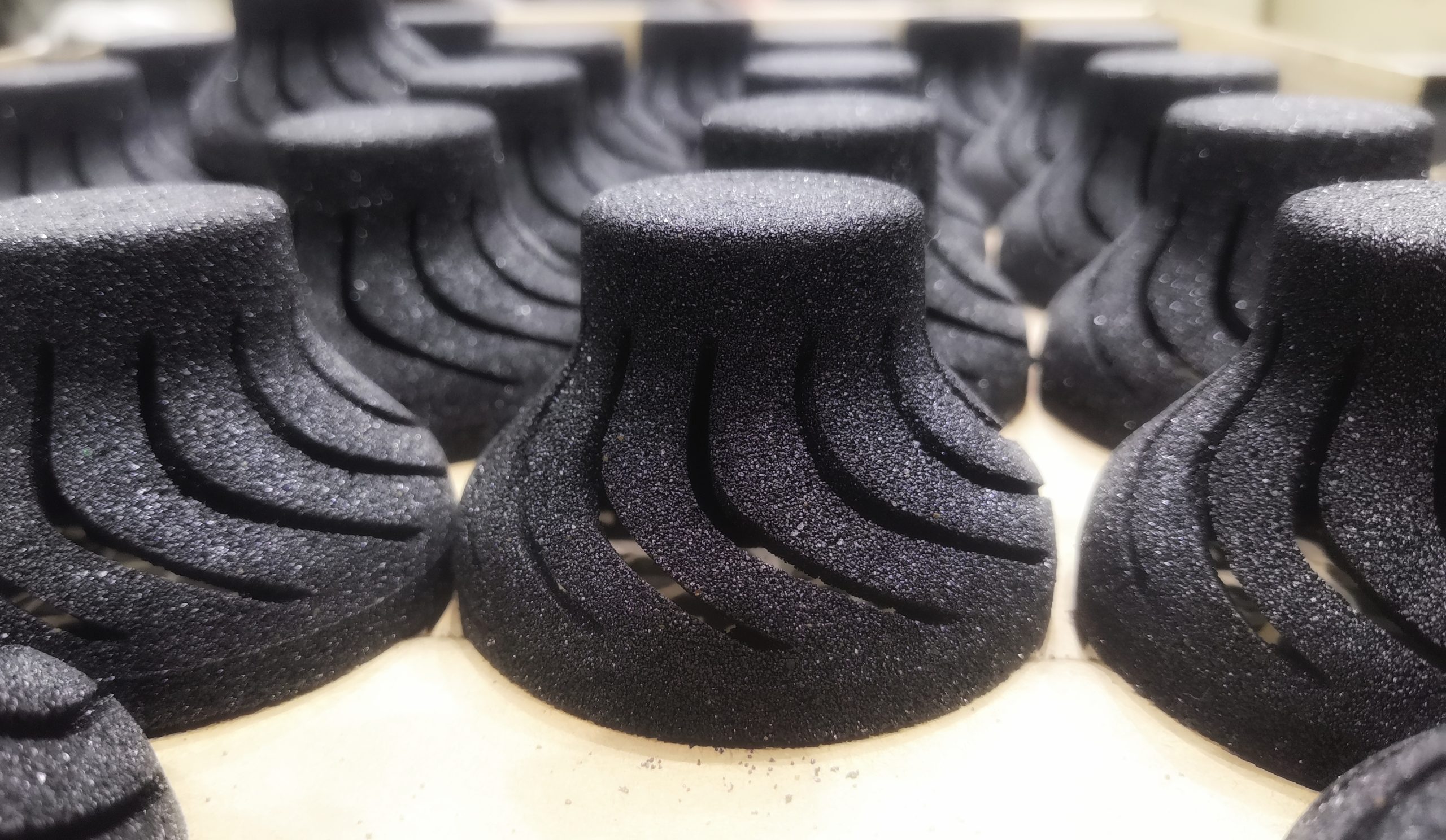

Ceramasite is produced from fusing high quality Bauxite then rapidly supercooling to form spherical shaped beads.

Used as a foundry mould or core sand it has the following characteristics:

Various grades are available including AFS 50 and 65.

We offer a full range of packaging requirements.

MSDS and TDS are available upon request.

Chrome Flour

Chrome flour is extensively used in the glass industry as a colourant in the production of green glass.

Processed from chrome fines, it has a minimum Cr2O3 content of 45%.

Processed in the UK at our grinding facility, we can achieve > 97% passing 45 microns

A mixing operation is also available if blending is required

We offer a full range of packaging requirements.

MSDS and TDS are available upon request.

Iron Oxide

Our Iron Oxide can be graded to be used as a colourant in the production of Amber glass.

A mixing operation is also available if blending is required.

We offer a full range of packaging requirements.

MSDS and TDS are available upon request.

High Friction Surfacing (HFS) is a surface treatment which increases the skid resistance on asphalt (Tarmac)roads. Materials used for this tend to be Calcined Bauxites. Calcined Bauxite is produced by sintering High-Alumina Bauxite in rotary, round, or shaft kilns at high temperatures. This process of calcining (heating) Bauxite in kilns removes moisture and gives Calcined Bauxite its High Alumina content and refractoriness, low iron, and grain hardness and toughness.

Al2O3 content of 82%.

Both buff and grey Bauxite are available in 1-3mm sizes.

PSV and AAV are tested in accordance with BBA regulations.

Can be utilised for both hot and cold applications.

Full range of packaging requirements are available.

MSDS and TDS available upon request.